PreciMill 5X

Compact, precise, innovative, and high-performance machining center for maximum productivity

Compact, precise, innovative, and high-performance machining center for maximum productivity

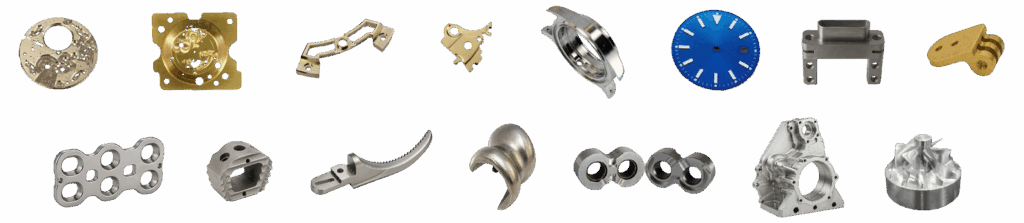

EMISSA designed the PreciMill to meet the increasing demands of the industry. A true concentration of advanced technologies, it is perfectly suited for high-precision applications such as watchmaking, micromechanics, connectors, and the MedTech sector. Compact, precise, and high-performance, the PreciMill has been developed with the same level of rigor and innovation as all our tailor-made machines, delivering optimal performance without compromising on technical specifications.

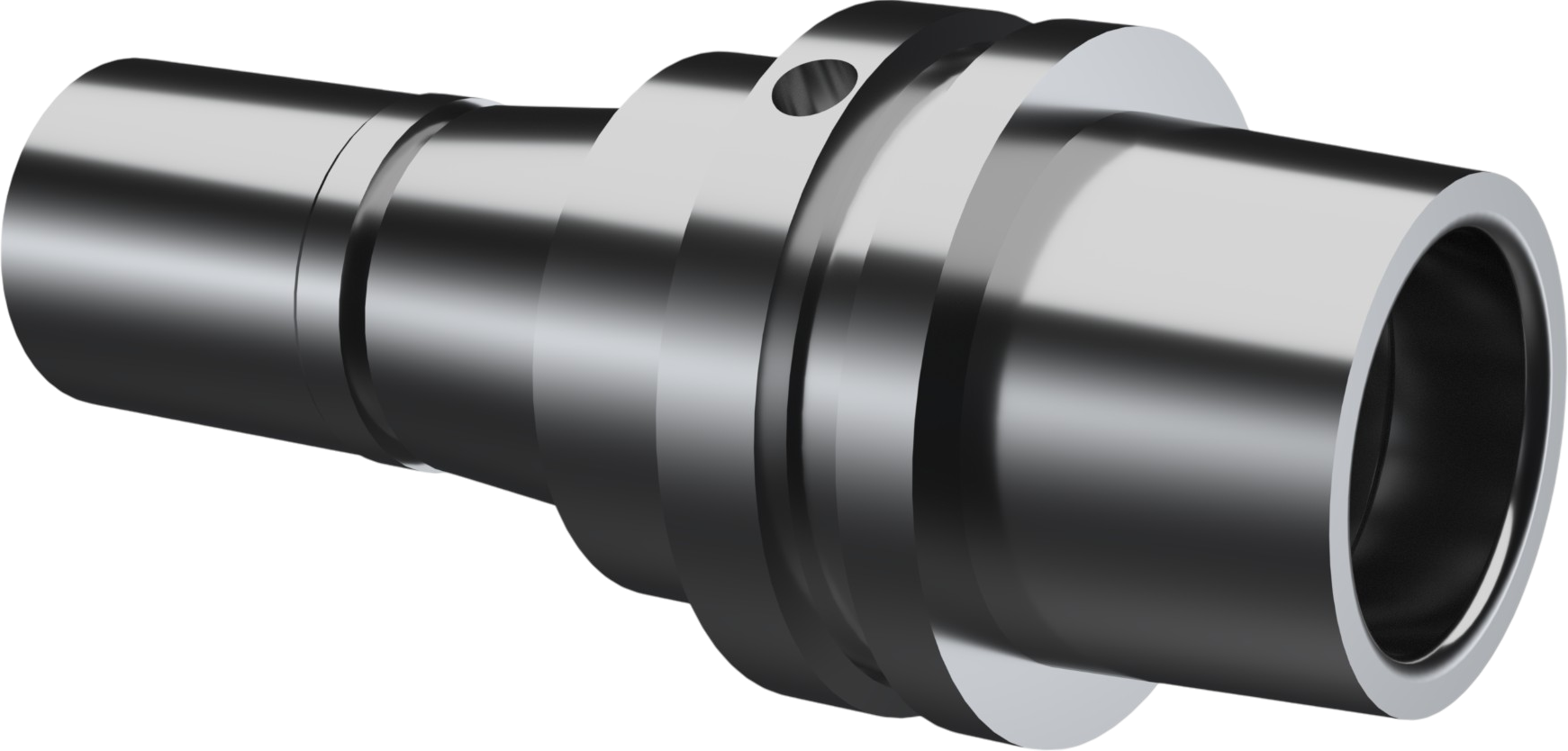

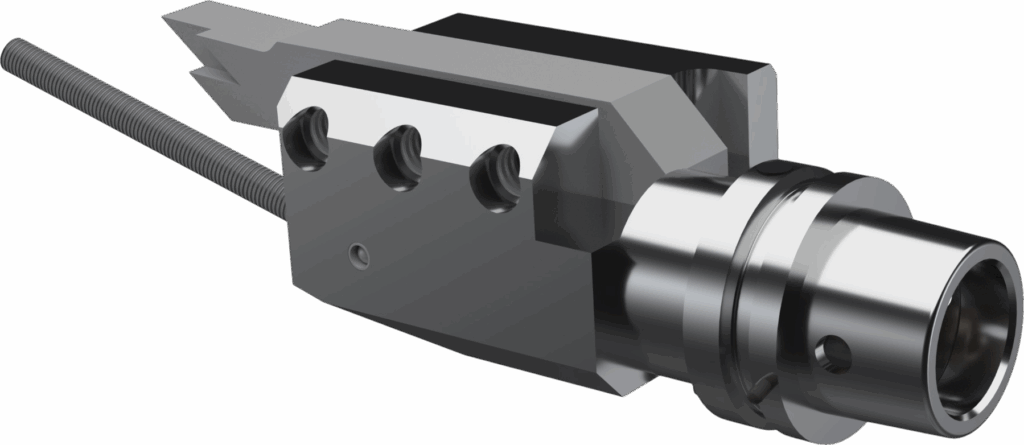

The PreciMill is equipped with a tailor-made Fischer high-frequency spindle

featuring an HSK-E25 tool interface, reaching speeds of up to 50,000 rpm. The

spindle includes a rotary union for high-pressure cooling through spindle at up to

120 bar, optimizing drilling speed, machining quality, and tool life.

It also features a stop block for locking turning tools, an axial thermal expansion

sensor, and an anti-static brush, ensuring maximum precision.

The design of the PreciMill machining center guarantees excellent precision and outstanding dynamics. Its mechanical structure has been carefully studied to achieve an optimum balance between static mass, which ensures a rigid and stable base for maximum precision, and moving mass, optimized thanks to a honeycomb cast-iron design, which considerably improves the machine’s responsiveness and dynamic performances.

The precision and repeatability of the PreciMill machining center are also guaranteed by its axis system, equipped with direct-drive linear and torque motors. The axes are thermally regulated to minimize expansion and are equipped with optical encoders. Strokes of 180 x 140 x 160 mm enable machining of mechanical parts up to 120 x120 x 120 mm.

PreciMill is compatible with industry-standard milling and drilling tool holders

For turning, the tool holders are specific. They are indexed and locked using a stopblock mounted under the spindle housing.

PreciMill features a laser tool measurement system to guarantee high machining accuracy and consistent process repeatability.

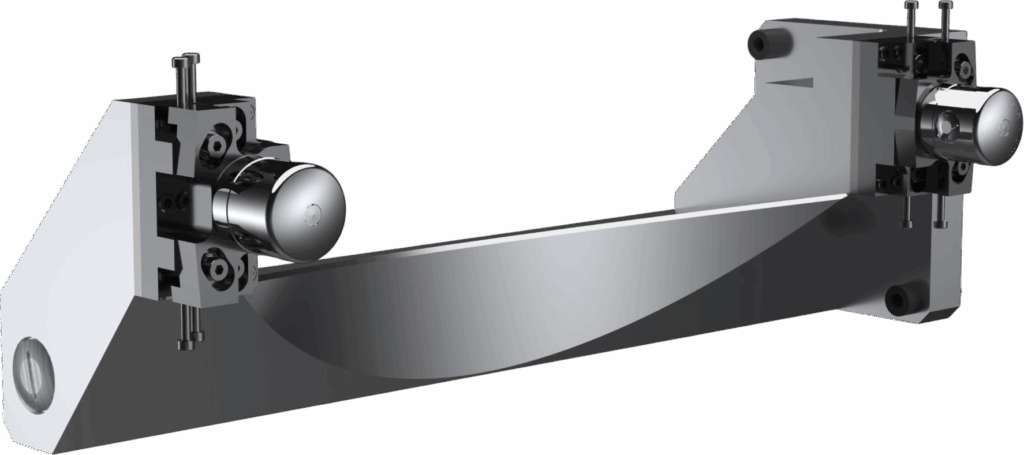

Equipped with a doublegripper rotary arm, the changer system enables rapid and accurate tool exchanges.

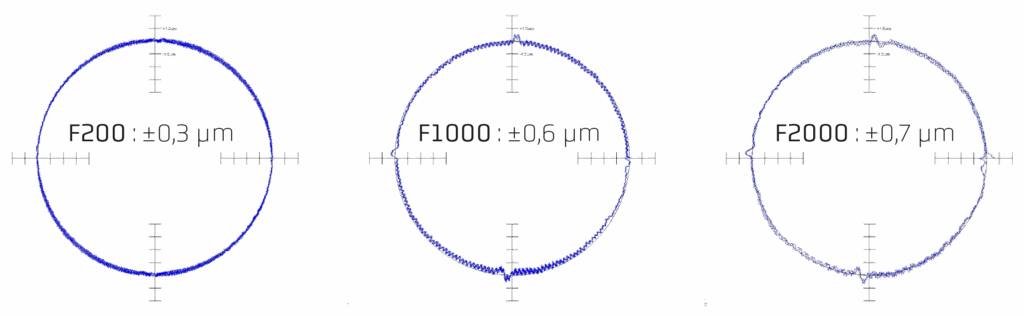

Circularity tests show PreciMill’s excellent dynamic behaviour.

Motorisation

Fanuc linear motors

X / Y / Z stroke

180 / 140 / 160

mm

Max. speed

60

m/min

Max. Acceleration

1

G

Optical linear coders

Heidenhein

Accuracy

180 / 140 / 160

um

Locking brake

On all axis

Diameter

61,91

mm

Interface

HSK-E25

Nominal / max. speed

40’000 / 50’000

rpm

Power S1 / S6

2,3 / 5,7

kW

Torque S1 / S6

0,6 / 1,4

Nm

Weight

5

kg

Dilatation sensor

Integrated

Stop block for turning tool

Integrated

Motor

Torque motor ETEL

Stroke

-110 à +40

°

Max. speed

250

rpm

Max. Acceleration

160

rad/s2

Optical angle coder

Heidenhein

Motor

Torque motor ETEL

Max. speed

4’200

rpm

Max. Acceleration

1’600

rad/s2

Optical angle coder

Heidenhain

Rotary union

Integrated

Workpiece blowing

Integrated

Numerical control

Fanuc 31i-B5 Plus

Simultaneous axis

Up to 5

Rigid tapping

From S0.6 to M5

Micro rigid tapping

From S0.3 to S0.6

Tools quantity

100

Tools diameter

40

mm

Max. tool diameter

70

mm

Max. tool length

105

mm

Max. tool weight

2

kg

Tool-to-tool changeover time

2,6

s

Chip-to-chip changeover time

3,8

s

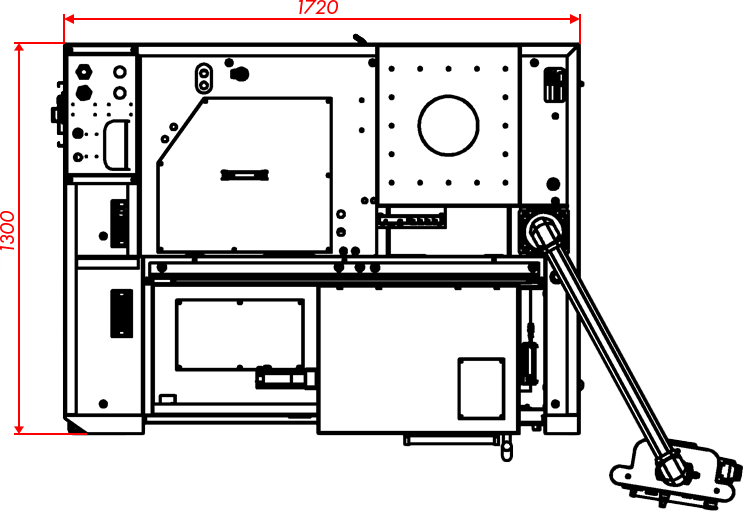

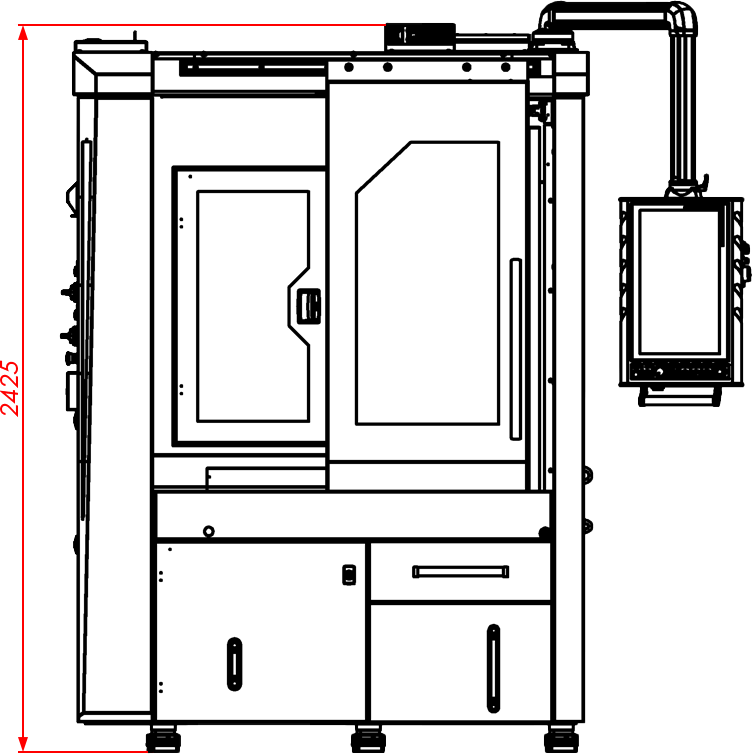

Width x Depth x Height

1’720 x 1’300 x 2’450

mm

Floor surface

2,24

m2

Weight

2’500

kg